SERVICES

Our services

When we say that we are always by the client’s side, we truly mean always: whatever the need, our technicians are ready to provide all the necessary assistance, with the timeliness and precision that define us.

From design, measurements, and verifications to supply lists, programs, inspections, and testing. Nothing is left to chance.

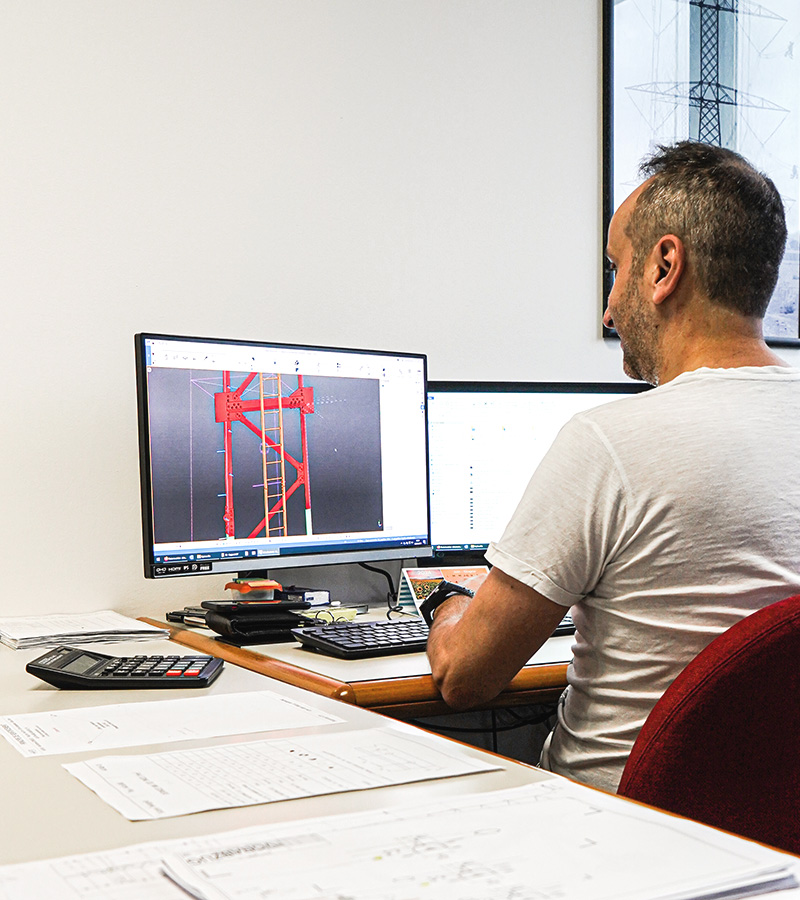

Design, sizing and verification

Experience, expertise, and technology: with the support of expert collaborators and the most up-to-date software, CDC can handle the design, sizing, and verification of metal structures and foundations.

Our past and present collaborations with highly experienced professionals and companies have allowed us to complete significant projects in Italy and around the world, such as the Foster Tower, the Vitruvio Tower, and the Cesar Pelli Tower.

On-site evaluation

CDC is continuously engaged in the development of new projects and is also the ideal partner when it comes to working on existing energy transmission lines. Often, after several years, the original documents of the structure are no longer available. This is why an on-site evaluation becomes essential to obtain an accurate assessment of the situation.

The on-site survey allows us to gather all the necessary information for creating new documents, which are indispensable in, for example, the restoration of deteriorated structures, those damaged by severe weather events, or those that need to be upgraded to meet new regulations, including through specific reinforcement projects for existing structures.

Construction drawings

While CDC’s expertise can add value in various stages of a project, construction drawings are undoubtedly our main and most recognized strength. Over the years, we have developed several work standards that, thanks to their effectiveness, are still in use and in demand by various companies. We have always believed that a clear and well-executed construction drawing is of fundamental importance, as it constitutes the foundation for all subsequent stages of the process, from material production by the manufacturer to on-site assembly by the installer. A key, non-negotiable feature of all our construction drawings is that all dimensions are always in real scale.

We can create construction drawings to meet any requirement, including:

• 2D drawings (Autocad);

• 3D drawings (Tekla and Bocad);

• Drawings in multiple languages (Italian, English, French, Spanish, German);

• Drawings with metric units (millimeters);

• Drawings with imperial units (feet and inches);

• Drawings with variable rounding precision (half a millimeter or tenth of a millimeter);

• Full-scale 1:1 detail drawings;

• Drawings with custom colors and layers;

• Individual drawings for production (A4 – A3 format);

• Other drawings unpon request.

REINFORCEMENT DRAWINGS FOR EXISTING STRUCTURES

Among the services offered by CDC is the creation of reinforcement drawings for existing structures. After many years of installation, these structures often require reinforcements. For over 25 years, CDC has collaborated with various companies to modernize these structures, addressing issues such as damage caused by pollution or weather events, or simply the need to upgrade them to comply with new regulations.

Our extensive experience in this field has allowed us to develop highly precise and detailed intervention standards to preserve existing structures. Depending on the case, the documents produced can be used for the production and replacement of damaged parts, reinforcement of specific sections, or even the entire structure. The documents also include the methods and sequence of the intervention.

DRAWINGS IN MILLIMETERS

DRAWINGS IN FEET/INCHES

Supply lists

While the creation of construction drawings is the core of the project, the preparation of supply lists is essential to ensure a smooth and precise management of the entire process that follows. Over the years, in response to our clients’ feedback and through continuous and fruitful collaboration with them, we have developed a custom supply list designed to meet all the needs that have arisen over time.

This is a comprehensive yet simple and intuitive document, allowing the user to independently select and manage the various stages of supply. The supply lists can be in Italian, English, French, Spanish, or German.

CNC machine programs – production files

This is where the production process truly begins: once the construction drawings are completed and the corresponding supply lists are prepared, the next step is the creation of the machine programs that enable the physical production of the various components.

Depending on the type of machine tool used for production, CDC can provide all the necessary information in .CAM, .PCS, or .NC formats.

Assembly assistance

CDC can provide support at every stage of the assembly process, which can vary depending on the location of the structure’s installation. Whether it’s manual assembly, assembly with a derrick, helicopter, or crane, CDC technicians will offer all the necessary details and instructions, based on the provided information, to ensure a safe, smooth, and hazard-free assembly operation.

Test station assistance

Among the various services offered by CDC is assistance at pole test stations, leveraging significant prior expertise. Thanks to the experience gained at the Garabuso pole test station in Lecco, CDC technicians are well-equipped to provide support for pole testing.

Depending on the characteristics of the test station, we design custom details for attaching cables to the structure, where the force will be applied to simulate in-service performance. These are temporary details that must be accurately sized to ensure they do not distort the test results.

Inspection and testing at production sites

The inspection and testing phase at production sites is crucial and delicate, requiring the outmost attention and reliance on competent personnel to ensure the safety and proper functioning of the structure.

The control procedures are extensive and cover all aspects of the structure, including:

• Verification of the prototype during trial assembly (structural and dimensional);

• Material control (quality control with “color code,” tensile tests on profiles and plates, HRB Rockwell test for bolts, shear tests on bolts, compression tests on bolts);

• Weld inspection (visual and dimensional checks, verification of compliance with technical specifications, radiographic and/or ultrasonic examination);

• Hot-dip galvanizing control (visual inspection, dimensional testing with micron gauge, precedence testing, stripping test, adhesion testing with Widia);

• Pole type testing (calibration checks of load cells, maneuver layout checks).